As per the statement from Mikhail Turundev, the director-general of Rosatom Additive Technologies, the evolution of metal powders obtainable on the global 3D printing market stimulated in 2020 and require methods for their integration into production and supply chains in Russia.

For example, the Russian giant EOS has about a hundred 3D printing systems functional in Russia, and plans to add more are in consideration. Companies that are into energy, aerospace, defense as well as shipping industries are expanding 3D printing facilities and metal powders for speeding up the integration of the supply chain in the year 2021.

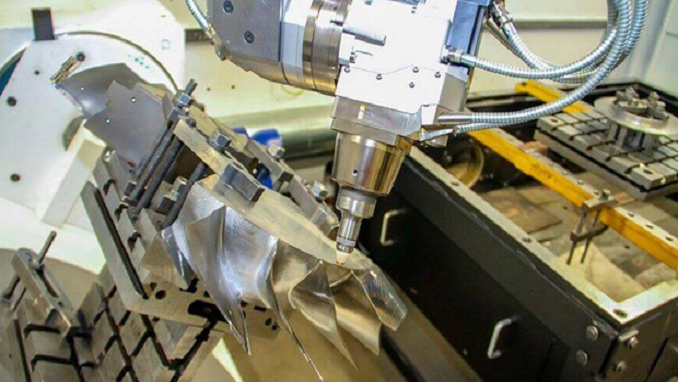

It is to be noted how utilization of metal powders, particularly alloys of aluminum, titanium, steel, copper, nickel, and cobalt is increasing in intricate industrial applications for personalizing complex components, to reduce the part weight and streamline the complete production process.

What’s planned for the Russian company RusAT in 2021?

This company provides ancillary to TVEL Fuel Company, part of a Russian state governed nuclear firm named Rosatom, inaugurated its first center of Additive Technologies at the Moscow Polymetal Plant. For making metal powders, post-processing equipment, and doing the product research to burgeon additive manufacturing technologies, there has been an installation of 3D printers on the plant. The plant also aims to manifest the chances of using additive technologies in industrial enterprises.

A complete additive manufacturing cycle is already on cards to be brought into place by the end of 2021. Turnadev also added how the second stage of enlargement is going to add more developed equipment to the plant. These equipment will be using selective laser sintering and stereolithography technologies. They’ll increase the range of testing and auxiliary equipment. Once that is done, the aim is to reach 300 million roubles by 2030.

History of RusAT

RusAt was formed in the year 2018 in integration with Rosatom’s additive manufacturing operations and determined to focus on four important areas:

1) For producing a line of 3D printers and components.

2) For spreading metal powders and other materials needed for 3D printing.

3) For creating integrated software used for additive manufacturing systems.

4) For providing services that support the use of 3D printing.

Apart from the Association for Development of Additive Technologies, RusAT’s list of other founding members include Almaz-Antey, the defence system producer, Gazpromneft – the Oil and Gas firm, the Russian Scientific Research Institute of Aviation Materials, Tekhnomash, and the Cat. RusAT collaborated with the Russian industry association that strives to unite the efforts of companies that specialize in this field with the state-owned enterprises that are rising in the field of 3D printing.

Targets for the coming years

As mentioned above, one of the aims that the association is striving to achieve is to multiply the growth of the Russian Additive technology market by 2.5 times. The target is to reach 170 billion roubles by the year 2030. This would mean that the association is investing 81 billion roubles for implementing measures in its development targets. Cat is a network, the first of its kind that endeavors to create ten additive technology centers by Rusatom by the year 2030. That’d be in coordination with the plan to create 180 centers as per Natalya Nikipelova, president of TVEL.

Stating about the upcoming center’s inauguration in Novouralsk at TVEL subsidiary Centrotech, it’ll launch the metal powders for 3D printing. This center would be a part of the development of additive technologies and run on the basis of RusAT’s newly made six new national industry standards approved in December. The two important standards deal with areas such as:

- a) The design and quality of metal powders.

- b) Laser alloying from a metal-powder composition of Ti-6Al-4V titanium alloy.

It is worth noting how twenty-eight standards already existed and for this year, the National Standardisation Program plans to add eleven more standards, taking the total to forty-five standards.

About the Russian engineering manufacturing company UEC-Saturn

It produces gas turbine engines for various industries such as commercial aerospace, power generation as well as shipping. UEC-Saturn has already achieved a successful outcome in making additive materials that can be utilized in marine gas turbines, and is still attempting to produce more and more in-house metal powders for replacing its system to import them. These are to be utilized in making marine gas turbines’ new designs.

Certifications were received by this company in the years 2019 and 2020 for metal powders established on Cobalt, Stainless Steel as well as Titanium alloy for aircraft gas turbine engines. Also, to mark how the first domestically produced additive materials Cobalt and Stainless Steel have also gained approval to be used in marine applications.

The Conclusion

The progress of companies such as RusAT, UEC Saturn, the association Cat shows how promising the Russian market of additive manufacturing is going to be throughout 2021. With the application of new standards that permit the liberal use of more types of 3D printing materials for making various parts and functional prototypes that find application in many industries; more and more people will gain the encouragement for starting their company in this field.

One noticeable benefit of 3D printing i.e. its flexibility over other manufacturing processes is going to be the main point of attraction. The fact that you can now develop a part or functional prototype by downloading its 3D design file from an online 3D printing repository is making everyone wonder about the advancement! Moreover, a lesser human intervention, which is the most important factor responsible for decreasing the quality of an object, is taken care of in 3D printing technology.

And in general scenario, not only about Russia but the complete world, there are more studies supporting the claim that 3D printing technology’s use is going to increase than decrease. Although there are some concerns that lead to the opposite conclusion, they are lesser in amount than otherwise. So be ready to face the rise of this modern manufacturing technology that dares you to reverse engineer for better.